Quality

Kamphuis Nijverdal specializes in performing quality tests in the coating industry. These tests are performed to verify whether the product and its environment meet strict requirements.

We possess over specialists and equipment to perform and report tests ourselves. If a customer requires a NACE-inspector, we involve a third party based on experience gained with external parties. An inspection report (English/Dutch) is the result of these inspections, according to high standards of the end user.Wij beschikken over specialisten en apparatuur om testen zelf uit te voeren en te rapporteren. Indien door de klant een NACE-inspecteur wordt geëist, schakelen wij een derde partij in op basis van opgedane ervaringen met externe partijen. Resultaat van deze inspecties vormt een inspectierapport (Engels-Nederlands) volgens hoogwaardige eisen van de eindgebruiker.

We work according to NEN-EN-ISO 12944. This is an international standard for corrosion protection of steel structures by protective paint systems. NEN-EN-ISO 12944 can be subdivided into:

- Part 1 – General introduction

- Part 2 – Classification of environments

- Part 3 – Design considerations

- Part 4 – Types of surface and surface preparation

- Part 5 – Protective paint systems

- Part 6 – Laboratory performance test methods and associated assessment criteria

- Part 7 – Execution and supervision of paint work

- Part 8 – Development of specifications for new work and maintenance

- Part 9 – Protective paint systems and laboratory performance test methods for offshore and related structures

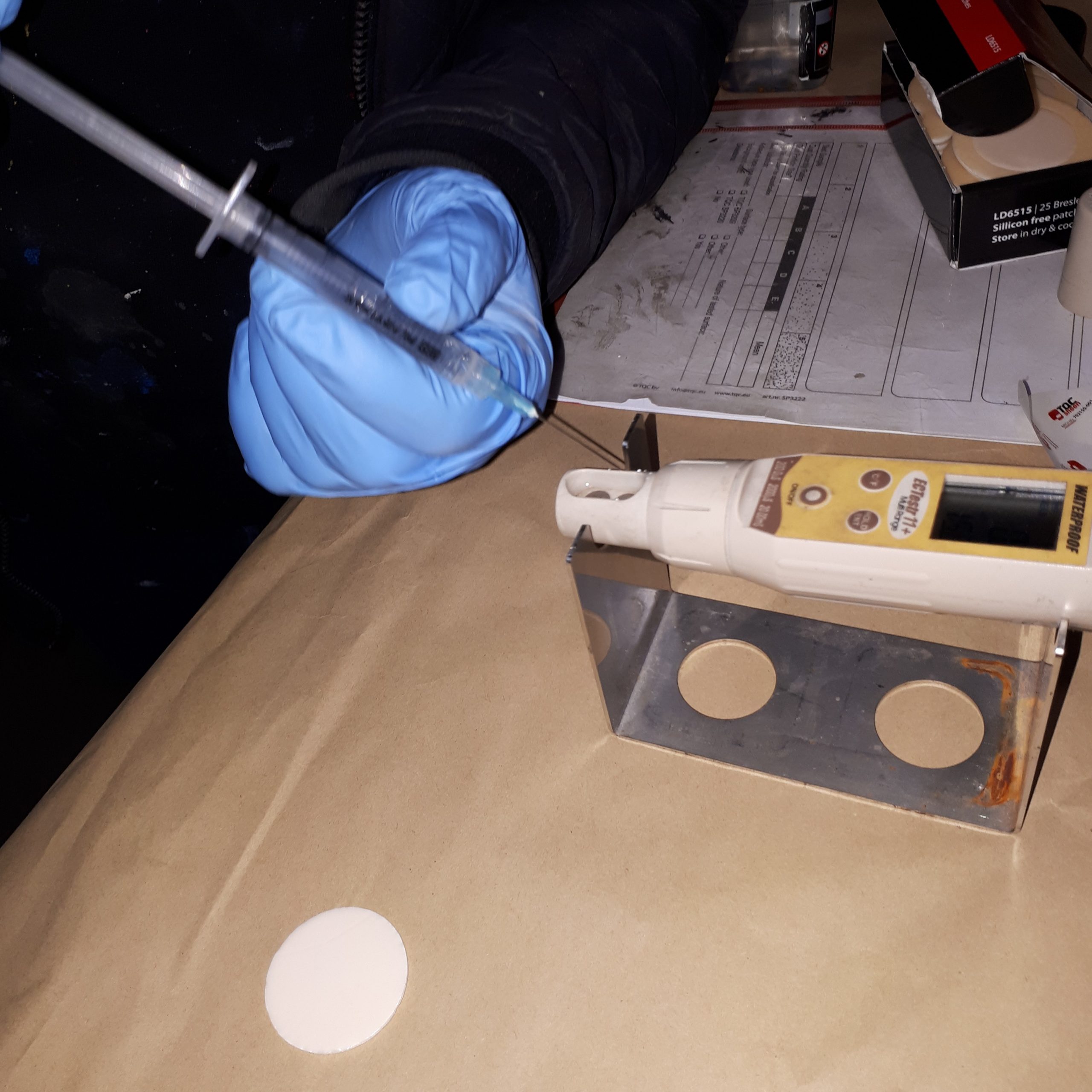

Certified quality measurements

Examples of quality tests we can perform:

Conditions of untreated surface:

- Visual inspection of surface on oils and greases according to SSPC-SP1

- Visual inspection of metal design according to SSPC-SP2 / ISO 12944-3

- Visual inspection of imperfections of steel and welds according to ISO 8501-3

- Presence of water-soluble contaminations (salts) according to ISO 8502-6/9 through a Bresle-test before blasting

- Presence of water-soluble contaminations (salts) in blasting grit according to ASTM D4940

- Presence of water-soluble contaminations (chloride, sulphate & nitrate), if desired through a CHLOR-test (with help of an external agency).

Conditions of blasted or metallized surface:

- Visual inspection of blasting or metallizing cleanliness according to ISO 8501-1

- Layer thickness measurements of metallizing work according to ISO 2178

- Presence of dusts according to ISO 8502-3 (size and amount of particles)

- Environmental conditions with climate data according to ISO 8502-4

- Visual inspection of blasting roughness according to ISO 8503-1/2

- Blasting roughness according to ISO 8503-4

- Presence of water-soluble contaminations (salts) according to ISO 8502-6/9 through a Bresle-test after blasting

Coating inspection:

- MEK Rub test according to ASTM D4752

- Dry layer thickness measurements according to ISO 19840

- Wet layer thickness measurements

- Visual inspection of applied coating layer

- Pore testing through low voltage (wet sponge) and high voltage method according to NACE RP0188

- Adhesion test through ‘Pull off test’ according to ISO 4624

- Adhesion test through ‘X-cut’ according to ASTM B3359