Application

It is of high importance that a part is given a paint layer. This important for both the design and for surface protection. A good painting system with the right pre-treatment protects the part against oxidation, elongating its lifetime. Costs and benefits of a treatment should of course be in accordance. Machines placed inside require a different approach than trailer manufacturing or offshore material that is outside in all kinds of weather.

Possibilities

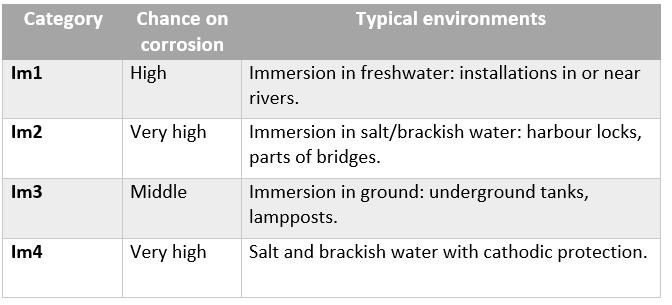

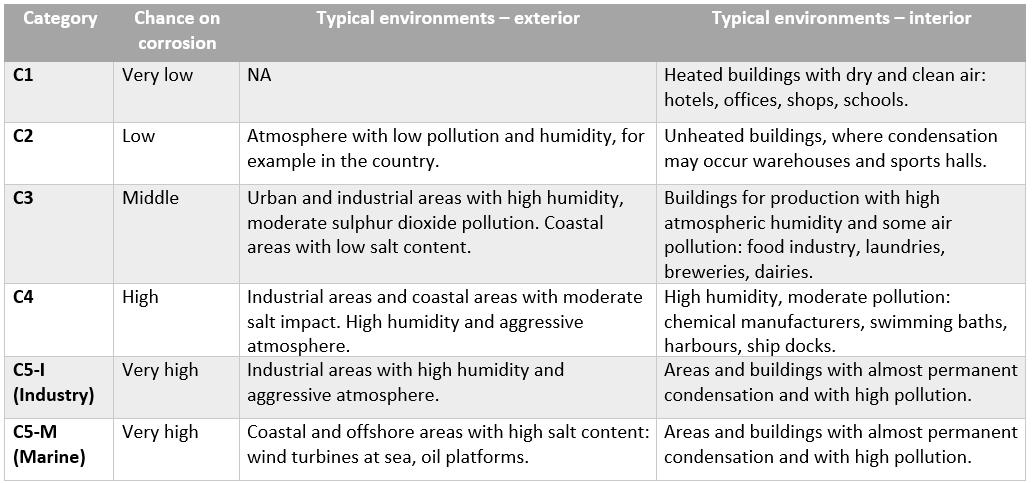

Each treatment has its own matching paintwork that meets the relevant requirements. Type and thickness of the paintwork are therefore carefully aligned. We can paint products on quality levels from C1 up to CX. If desired, your product can be provided with quality reporting regarding painting systems C1 up to CX and Im1 up to Im3. For more information: see Quality. We only make use of painting systems from renowned producers (Akzo Nobel, Zandleven, International Paint and PPG), with a minimal percentage of solvents.

Coating specification

Regarding quality management of the paint material, we work according to NEN-EN-ISO 12944. Part 5 of the ISO standard includes protective paint systems.

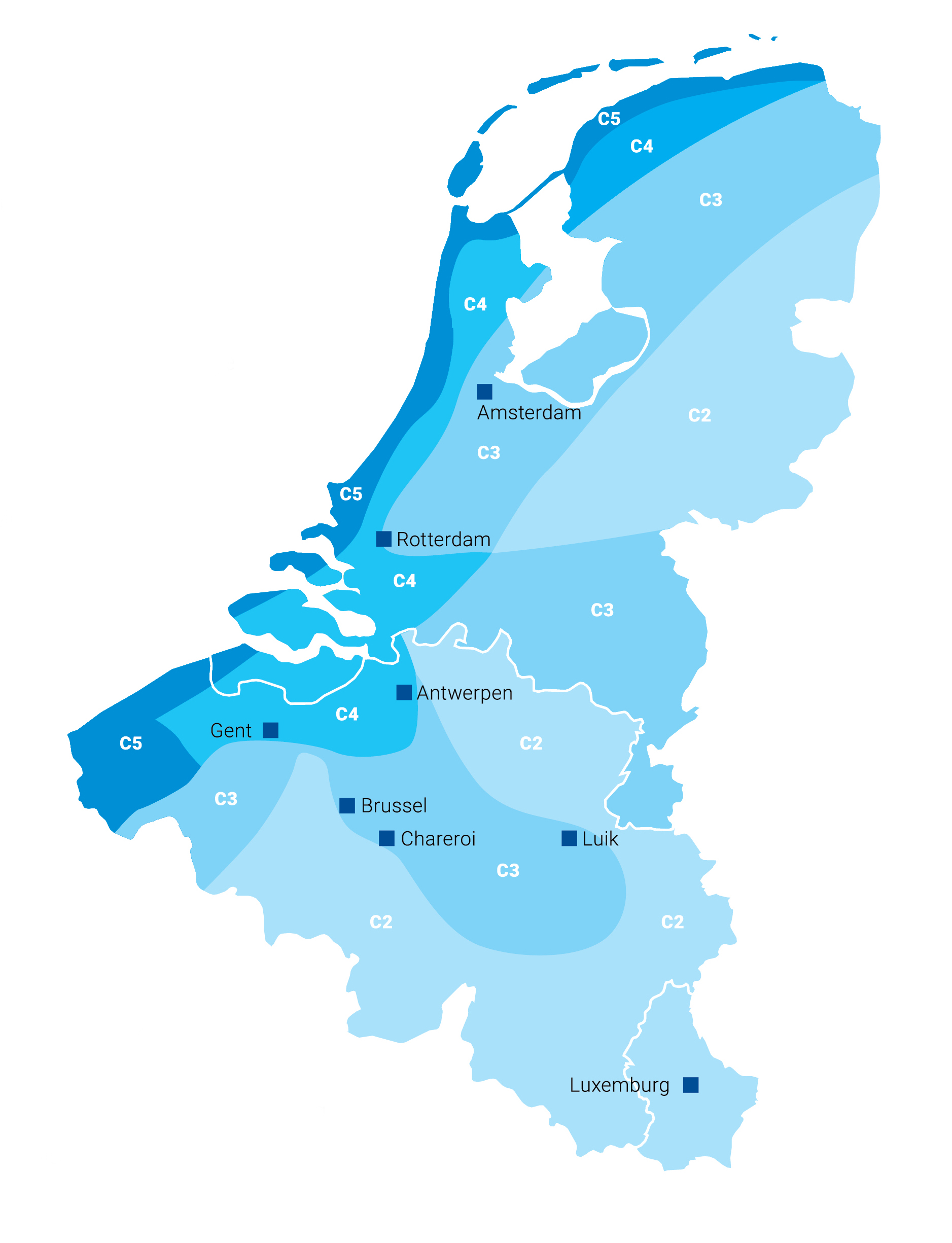

The environment can be divided in different sectors, namely C1 up to C5M (offshore CX). These sectors indicate how aggressive the atmosphere in a region is. See the map next to this.

In industrial areas, offshore and near the coast, the amount of salt and polluted atmosphere is high. A high classification therefore means that a higher quality painting system is required.

For example: a vehicle in winter season comes into contact with road salt. A vehicle therefore has classification C3, C4 or C5.

For advice regarding the coating specification and coating suitability of your product, you are at the right place with us.

Design considerations

Part 3 of ISO 12944 addresses the Design considerations. These are guidelines regarding the coating suitability of an object.

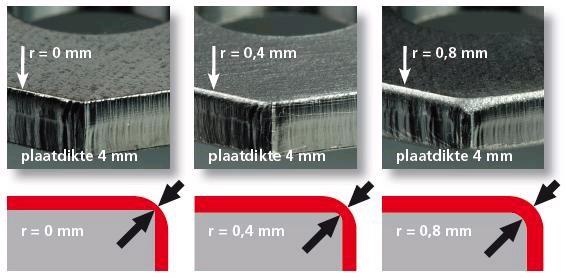

- No sharp corners. It is desired that all corners of a product have a minimal radius of 2 mm. On sharp corners, paint thickness cannot be created.

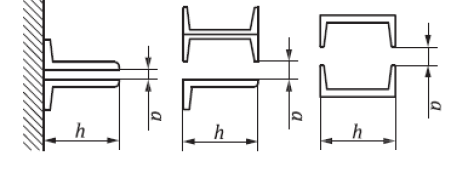

- It is important that construction parts have sufficient space between them. This space is required to fulfil the process successfully. The space (a) between the construction depends on the depth (h) of the construction.

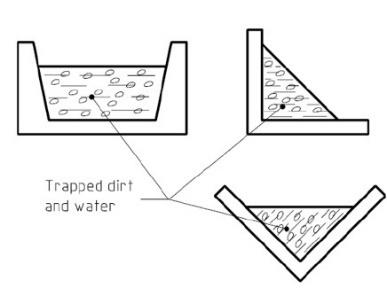

- No possibility of water accumulation. It is desired that enclosed spaces have an opening, to drain water. This way, not only is degradation of the paint prevented, it also allows for visual inspection.

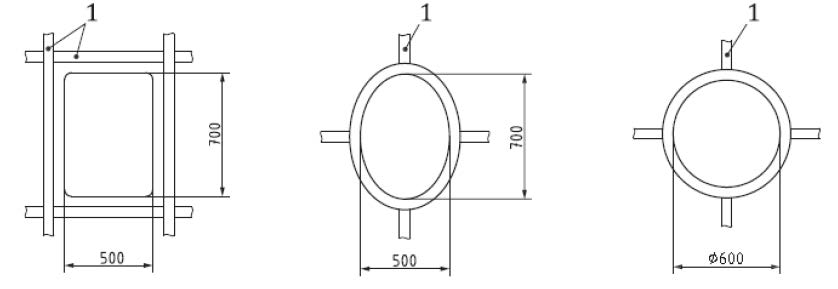

- There should be sufficient space to be able to treat a product from the inside. This prevents the operator from not being able to reach a surface that needs treatment.