Application

Blasting (also called sandblasting of metal) is an efficient way to remove corrosion and other contaminations from a metal subject, or better: to prevent it. It is a mechanical (pre)treatment and therefore also more environmentally friendly than treatment with chemicals. Kamphuis Nijverdal’s blasting process also meets the strictest environmental protection requirements.

Principle

During blasting, high quality blasting agent is propelled against the product under high pressure. The blasting agent hits the product at high force to remove contaminations, such as rust, all over the metal. The problem is then solved for a long time. What remains is a clean, rough base material that is suitable for further surface treatments, such as metallizing and/or painting.

For each product, we determine which blasting technique and intensity will be applied. This depends on aspects such as material type and thickness and the amount in which corrosion, mill scale and other contaminations are present. Before blasting, thread, turning parts, shafts and other vulnerable parts are protected. The process is then performed very carefully. Kamphuis Nijverdal uses two blasting agents:

- Corundum (non-metallic)

- Steel grit (metallic)

Both are used as a pre-treatment for preserving industrial products. These blasting agents clean the material, remove rust or remove a used paint layer. We can perform measurements and inspections before and after blasting. More information can be found under Quality.

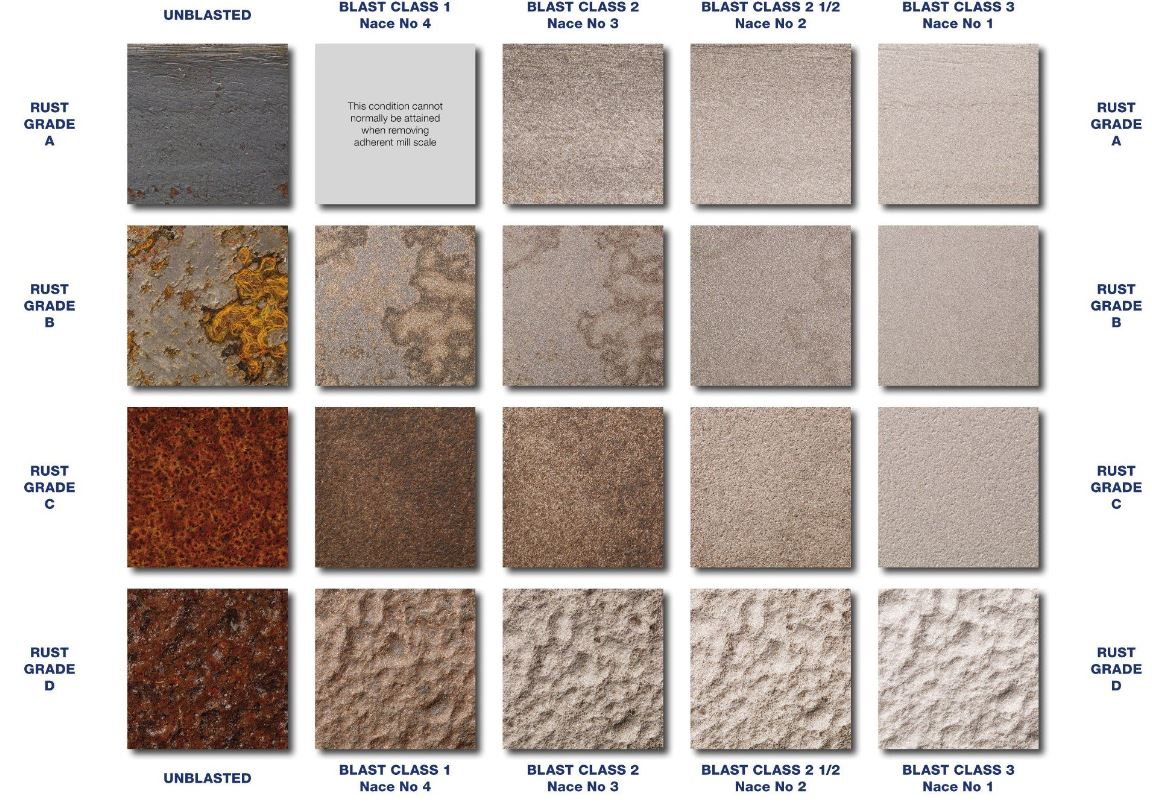

We work according to ISO 12944. Part 4 of the ISO 12944 consists of: Types of surface and surface preparation. Amongst others, table ISO 8501-1:2007 is used. These quality systems allow us to obtain the required quality for our work.

ST2 or ST3 indicates the cleanliness of the surface after a sanding or grinding treatment.

More information can be found under Other. Sa 1, Sa 2, Sa 2,5 and Sa 3 indicate the cleanliness of the surface after blasting.

First, the grade of rust and cleanliness are determined according to ISO 8501-1:2007.

Then the degree of the treatment is determined using ISO 8501-1:2007.

ISO 8501-1:2007